Veneer for Furniture

Wood River Veneer fabricates and sells component parts, panels and veneer for furniture to designers, builders, shops and individuals. We also fabricate pieces of furniture on a custom and sub-contarct basis. We have built a wide variety of tables, tops, bases and related component parts for residential and commercial applications. Beds and head and toe boards seem to be pretty popular as well. Media entertainment centers, dressers, night stands and free standing vanitys are all furniture pieces that we build or sell veneer and parts for. We are proud of the fact that we are a very diversified shop.

.jpg)

These are two variations out of several dining tables that we have built over the years with a similar type of base construction. In each case we used an open strut base construction with either a solid or glass top. The designer of these tables prefers these three woods as well as domestic Walnut, Sapele, Mahogany, Makore, Pearwood, Rift white Oak and Beech. We do not like exposed fasteners so we hide as much as possible. In the case of these tables nothing is exposed. The tops do separate from the base for moving, storage and possible repair purposes.

.jpg)

I really like Etimoe, especially when it is quarter figured and leans more to the brown side with black grain running through it. This home is perfect for Etimoe. The house is contemporary in style and has lots of light. The wood is dark and really stands out with natural light and white tones of paint. We have used Etimoe in darker settings as well and it looks just as nice. It's really hard to find Etimoe lumber so we usually use Peruvian Walnut when we need dimensional lumber to accompany the veneer. A lot of the Etimoe that we see isn't all that great so we have a tendency to look far and wide before we find a flitch we like. That doesn't mean that our customer is looking for the same thing so we work with what they like.

.jpg)

This cabinet appears as if it is a free standing piece of furniture when in reality it is built in. It doubles as a wet bar and buffet. We were asked to provide the component parts for this piece for another shop so we did. Both the veneer and the solid Afrormosia is quarter cut. The cabinet was finished with a medium brown glaze and several coats of satin lacquer.

We have produced several pairs of these radius nightstands in maple and Pearwood. They are very attractive but labor intensive to construct. When we build these, we pay great attention to detail and matching. These cabinets are not mass produced and do not look like it. We try not to get to carried away with really wild wood patterns primarily because the design makes a statement and the wood is there to back up the design, not dominate it. I think burled woods can work well with this design as long as we are careful not to over due a good thing.

This dining table was a tough table to build. We were asked to build this dining table so it could stand alone as three seperate tables or join together and create one. The key was that when the tables were not joined together, they had to look like they were not suppose to be joined together. When they were joined together, they had to look like one big table. Each section has a pedestal and each pedestal mimics the others. The important part is that we managed to come up with a design that worked and fourteen years later, the owners still have and use the table.

We had an architect come to us a few years ago with an idea and this is what the idea ended up looking like. I have to admit we were skeptical at first and were not quite sure how the heck we would construct the beds, we figured it out and ended up building four of them. It took a lot of laminating to build these posts. The hard part was keeping them straight!

We built this piece of furniture to match a dresser that was not available in a night stand size. Our customer wanted a night stand that would match the dresser they already had, so we were commissioned to build exactly that. The back of the cabinet has a media chase. We incorporated this feature in to accomodate the top drawer, which houses a pull out DVD player. Electrical and media cords enter and exit the cabinet from the bottom side rather than the back. The drawer faces are balance matched Walnut Burl and so is the top. The sides and back are plain Walnut. This was alot of fun to build.

This entire master suite, which includes the bedroom, closet and bath, built in cabinetry and furnishings, for the most part, are finished with quarter figured European Sycamore, figured North American Maple, Birds Eye Maple and Maple Burl. If you will notice, the quarter cut Sycamore is slip matched to avoid barber poleing. Barber pole is when veneer leaves are dark then light then dark again and so on and so on. One reason this happens is that, when veneer gets sliced, one side of the blade opens the grain more and the other side of the blade closes the grain more. When you combine that with the grain appearance you are after, such as quarter cut versus flat cut, and the species you are cutting, you can easily have shade problems. Slip matching quarter figured veneer can work really well if the figure is running very parallel to the grain of the wood. It can be a lot easier to slip match flat cut.

.jpg)

A few years ago, we provided a condominium complex in Florida with panels, columns, pilasters, fixtures, wainscot and trim. Accept for the media area, which is pommele Bubinga, most of the project is plain sliced South American Mahogany. We built everything here in Idaho, packed up a semi trailer, and shipped it all to West Palm Beach, Florida. Due to the heads-up thinking of the two designer partners involved in the project, everything survived hurricane Charley by sitting it out in a warehouse well inland of the beach property the complex sits on. Eventually, the mess was cleaned up and the project was finished. This is what it looks like today.

.jpg)

We built these two dining tables as a pair. The smaller table is a 48" round that opens to a 48"x72" table with a split pedestal. The larger table is a 72" round that opens to a 72"x96" table with a split pedestal. It took just over 1000 hours to build these two tables. The tops are made with quarter figured black Walnut and have an Ebony inlay that separates the field from the border. We constructed both borders with 12/4 all heart Walnut. The round pedestal bases are built with plain quartered walnut and more 12/4 Walnut. They split and create half pedestals when the center leaf is installed. I really like these tables and would like to build a similar one for myself some day.

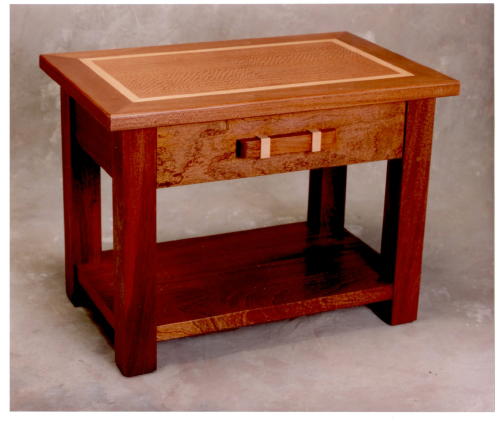

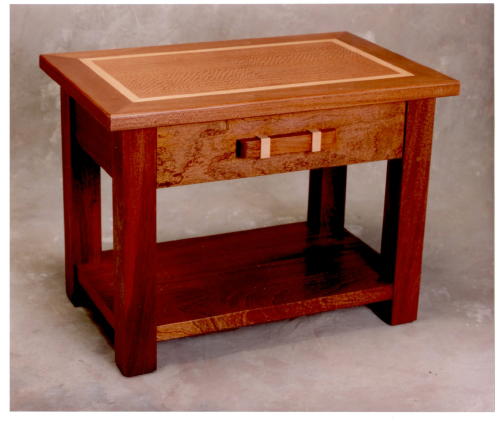

This cabinet is one of a pair that we built for a customer to be used as end tables for a sofa. They actually were part of several piece set that were different combinations of European Beech and African plain and fiddleback Sapele. The top of this table has a field of fiddleback Sapele veneer with a European steamed Beech veneer inlay separating it from the solid plain Sapele border. The body of the cabinet is constructed with solid Sapele.

This media center is one of several we have manufactured over the years. We have also supplied many cabinet shops with the necessary component parts for their own Media/Entertainment Center projects. Our customer wanted this cabinet to be a free standing piece of furniture and be able to be moved easily if necessary. To accomplish this task we took the design she furnished us with and constucted the cabinet as three separate components that would integrate and function as a single piece. It was fitted with a component rack system, a cooling system and a hidden chase system. The chase system allowed necessary cables that link the media equipment together to travel freely from one section to the next and remain inconspicuous. This cabinet has since been relocated to a new home in another state.

.jpg) These are two variations out of several dining tables that we have built over the years with a similar type of base construction. In each case we used an open strut base construction with either a solid or glass top. The designer of these tables prefers these three woods as well as domestic Walnut, Sapele, Mahogany, Makore, Pearwood, Rift white Oak and Beech. We do not like exposed fasteners so we hide as much as possible. In the case of these tables nothing is exposed. The tops do separate from the base for moving, storage and possible repair purposes.

These are two variations out of several dining tables that we have built over the years with a similar type of base construction. In each case we used an open strut base construction with either a solid or glass top. The designer of these tables prefers these three woods as well as domestic Walnut, Sapele, Mahogany, Makore, Pearwood, Rift white Oak and Beech. We do not like exposed fasteners so we hide as much as possible. In the case of these tables nothing is exposed. The tops do separate from the base for moving, storage and possible repair purposes..jpg) I really like Etimoe, especially when it is quarter figured and leans more to the brown side with black grain running through it. This home is perfect for Etimoe. The house is contemporary in style and has lots of light. The wood is dark and really stands out with natural light and white tones of paint. We have used Etimoe in darker settings as well and it looks just as nice. It's really hard to find Etimoe lumber so we usually use Peruvian Walnut when we need dimensional lumber to accompany the veneer. A lot of the Etimoe that we see isn't all that great so we have a tendency to look far and wide before we find a flitch we like. That doesn't mean that our customer is looking for the same thing so we work with what they like.

I really like Etimoe, especially when it is quarter figured and leans more to the brown side with black grain running through it. This home is perfect for Etimoe. The house is contemporary in style and has lots of light. The wood is dark and really stands out with natural light and white tones of paint. We have used Etimoe in darker settings as well and it looks just as nice. It's really hard to find Etimoe lumber so we usually use Peruvian Walnut when we need dimensional lumber to accompany the veneer. A lot of the Etimoe that we see isn't all that great so we have a tendency to look far and wide before we find a flitch we like. That doesn't mean that our customer is looking for the same thing so we work with what they like..jpg) This cabinet appears as if it is a free standing piece of furniture when in reality it is built in. It doubles as a wet bar and buffet. We were asked to provide the component parts for this piece for another shop so we did. Both the veneer and the solid Afrormosia is quarter cut. The cabinet was finished with a medium brown glaze and several coats of satin lacquer.

This cabinet appears as if it is a free standing piece of furniture when in reality it is built in. It doubles as a wet bar and buffet. We were asked to provide the component parts for this piece for another shop so we did. Both the veneer and the solid Afrormosia is quarter cut. The cabinet was finished with a medium brown glaze and several coats of satin lacquer.  We have produced several pairs of these radius nightstands in maple and Pearwood. They are very attractive but labor intensive to construct. When we build these, we pay great attention to detail and matching. These cabinets are not mass produced and do not look like it. We try not to get to carried away with really wild wood patterns primarily because the design makes a statement and the wood is there to back up the design, not dominate it. I think burled woods can work well with this design as long as we are careful not to over due a good thing.

We have produced several pairs of these radius nightstands in maple and Pearwood. They are very attractive but labor intensive to construct. When we build these, we pay great attention to detail and matching. These cabinets are not mass produced and do not look like it. We try not to get to carried away with really wild wood patterns primarily because the design makes a statement and the wood is there to back up the design, not dominate it. I think burled woods can work well with this design as long as we are careful not to over due a good thing.  This dining table was a tough table to build. We were asked to build this dining table so it could stand alone as three seperate tables or join together and create one. The key was that when the tables were not joined together, they had to look like they were not suppose to be joined together. When they were joined together, they had to look like one big table. Each section has a pedestal and each pedestal mimics the others. The important part is that we managed to come up with a design that worked and fourteen years later, the owners still have and use the table.

This dining table was a tough table to build. We were asked to build this dining table so it could stand alone as three seperate tables or join together and create one. The key was that when the tables were not joined together, they had to look like they were not suppose to be joined together. When they were joined together, they had to look like one big table. Each section has a pedestal and each pedestal mimics the others. The important part is that we managed to come up with a design that worked and fourteen years later, the owners still have and use the table.  We had an architect come to us a few years ago with an idea and this is what the idea ended up looking like. I have to admit we were skeptical at first and were not quite sure how the heck we would construct the beds, we figured it out and ended up building four of them. It took a lot of laminating to build these posts. The hard part was keeping them straight!

We had an architect come to us a few years ago with an idea and this is what the idea ended up looking like. I have to admit we were skeptical at first and were not quite sure how the heck we would construct the beds, we figured it out and ended up building four of them. It took a lot of laminating to build these posts. The hard part was keeping them straight! We built this piece of furniture to match a dresser that was not available in a night stand size. Our customer wanted a night stand that would match the dresser they already had, so we were commissioned to build exactly that. The back of the cabinet has a media chase. We incorporated this feature in to accomodate the top drawer, which houses a pull out DVD player. Electrical and media cords enter and exit the cabinet from the bottom side rather than the back. The drawer faces are balance matched Walnut Burl and so is the top. The sides and back are plain Walnut. This was alot of fun to build.

We built this piece of furniture to match a dresser that was not available in a night stand size. Our customer wanted a night stand that would match the dresser they already had, so we were commissioned to build exactly that. The back of the cabinet has a media chase. We incorporated this feature in to accomodate the top drawer, which houses a pull out DVD player. Electrical and media cords enter and exit the cabinet from the bottom side rather than the back. The drawer faces are balance matched Walnut Burl and so is the top. The sides and back are plain Walnut. This was alot of fun to build. This entire master suite, which includes the bedroom, closet and bath, built in cabinetry and furnishings, for the most part, are finished with quarter figured European Sycamore, figured North American Maple, Birds Eye Maple and Maple Burl. If you will notice, the quarter cut Sycamore is slip matched to avoid barber poleing. Barber pole is when veneer leaves are dark then light then dark again and so on and so on. One reason this happens is that, when veneer gets sliced, one side of the blade opens the grain more and the other side of the blade closes the grain more. When you combine that with the grain appearance you are after, such as quarter cut versus flat cut, and the species you are cutting, you can easily have shade problems. Slip matching quarter figured veneer can work really well if the figure is running very parallel to the grain of the wood. It can be a lot easier to slip match flat cut.

This entire master suite, which includes the bedroom, closet and bath, built in cabinetry and furnishings, for the most part, are finished with quarter figured European Sycamore, figured North American Maple, Birds Eye Maple and Maple Burl. If you will notice, the quarter cut Sycamore is slip matched to avoid barber poleing. Barber pole is when veneer leaves are dark then light then dark again and so on and so on. One reason this happens is that, when veneer gets sliced, one side of the blade opens the grain more and the other side of the blade closes the grain more. When you combine that with the grain appearance you are after, such as quarter cut versus flat cut, and the species you are cutting, you can easily have shade problems. Slip matching quarter figured veneer can work really well if the figure is running very parallel to the grain of the wood. It can be a lot easier to slip match flat cut. .jpg) A few years ago, we provided a condominium complex in Florida with panels, columns, pilasters, fixtures, wainscot and trim. Accept for the media area, which is pommele Bubinga, most of the project is plain sliced South American Mahogany. We built everything here in Idaho, packed up a semi trailer, and shipped it all to West Palm Beach, Florida. Due to the heads-up thinking of the two designer partners involved in the project, everything survived hurricane Charley by sitting it out in a warehouse well inland of the beach property the complex sits on. Eventually, the mess was cleaned up and the project was finished. This is what it looks like today.

A few years ago, we provided a condominium complex in Florida with panels, columns, pilasters, fixtures, wainscot and trim. Accept for the media area, which is pommele Bubinga, most of the project is plain sliced South American Mahogany. We built everything here in Idaho, packed up a semi trailer, and shipped it all to West Palm Beach, Florida. Due to the heads-up thinking of the two designer partners involved in the project, everything survived hurricane Charley by sitting it out in a warehouse well inland of the beach property the complex sits on. Eventually, the mess was cleaned up and the project was finished. This is what it looks like today. .jpg) We built these two dining tables as a pair. The smaller table is a 48" round that opens to a 48"x72" table with a split pedestal. The larger table is a 72" round that opens to a 72"x96" table with a split pedestal. It took just over 1000 hours to build these two tables. The tops are made with quarter figured black Walnut and have an Ebony inlay that separates the field from the border. We constructed both borders with 12/4 all heart Walnut. The round pedestal bases are built with plain quartered walnut and more 12/4 Walnut. They split and create half pedestals when the center leaf is installed. I really like these tables and would like to build a similar one for myself some day.

We built these two dining tables as a pair. The smaller table is a 48" round that opens to a 48"x72" table with a split pedestal. The larger table is a 72" round that opens to a 72"x96" table with a split pedestal. It took just over 1000 hours to build these two tables. The tops are made with quarter figured black Walnut and have an Ebony inlay that separates the field from the border. We constructed both borders with 12/4 all heart Walnut. The round pedestal bases are built with plain quartered walnut and more 12/4 Walnut. They split and create half pedestals when the center leaf is installed. I really like these tables and would like to build a similar one for myself some day.  This cabinet is one of a pair that we built for a customer to be used as end tables for a sofa. They actually were part of several piece set that were different combinations of European Beech and African plain and fiddleback Sapele. The top of this table has a field of fiddleback Sapele veneer with a European steamed Beech veneer inlay separating it from the solid plain Sapele border. The body of the cabinet is constructed with solid Sapele.

This cabinet is one of a pair that we built for a customer to be used as end tables for a sofa. They actually were part of several piece set that were different combinations of European Beech and African plain and fiddleback Sapele. The top of this table has a field of fiddleback Sapele veneer with a European steamed Beech veneer inlay separating it from the solid plain Sapele border. The body of the cabinet is constructed with solid Sapele.  This media center is one of several we have manufactured over the years. We have also supplied many cabinet shops with the necessary component parts for their own Media/Entertainment Center projects. Our customer wanted this cabinet to be a free standing piece of furniture and be able to be moved easily if necessary. To accomplish this task we took the design she furnished us with and constucted the cabinet as three separate components that would integrate and function as a single piece. It was fitted with a component rack system, a cooling system and a hidden chase system. The chase system allowed necessary cables that link the media equipment together to travel freely from one section to the next and remain inconspicuous. This cabinet has since been relocated to a new home in another state.

This media center is one of several we have manufactured over the years. We have also supplied many cabinet shops with the necessary component parts for their own Media/Entertainment Center projects. Our customer wanted this cabinet to be a free standing piece of furniture and be able to be moved easily if necessary. To accomplish this task we took the design she furnished us with and constucted the cabinet as three separate components that would integrate and function as a single piece. It was fitted with a component rack system, a cooling system and a hidden chase system. The chase system allowed necessary cables that link the media equipment together to travel freely from one section to the next and remain inconspicuous. This cabinet has since been relocated to a new home in another state.