Domestic Veneer

The term domestic veneer applies to those wood species that grow on the North American continent, Hawaii, Puerto Rico and the US Virgin Islands etc. Hardwood domestic veneer that is intended to be sold in the North American and Export markets is sliced from 1/45" to 1/55" these days. The exceptions would be softwood species like knotty pine at 1/32", clear pine at 1/30", Clear Vertical Grain (CVG) Douglas Fir at 1/42", Knotty Western Red Cedar at 1/32" and clear Western Red Cedar at 1/30". Some North American species are also sliced or resawn into special thicknesses such as 1/36", 1/32", 1/30", 1/28", 1/24", 1/20", 1/16", 1/12", 1/10", 1/8", 1/6" and 1/4" for plywood production and specialty needs. We primarily stock and sell Domestic Architectural grades in Plain Sliced, Quarter Cut, Rift Cut, Rotary Cut and Half Round configurations. This includes some domestic species of Burls which primarily are Walnut, Madrone, Myrtle and Maple.

Domestic Veneer

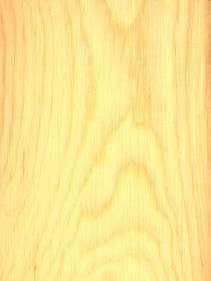

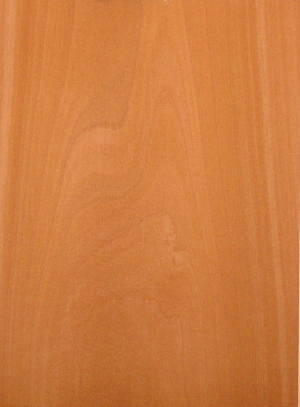

Alder can be found in many countries around the globe. We primarily stock West Coast red/brown Alder in plain sliced and quarter cut. Alder is one of those woods that started out as good firewood and then, due to its rustic appeal, worked its way into many homes and commercial buildings as an attractive and affordable wood for cabinets and finish work. Prices have increased and it has gotten a lot harder to find clear Alder veneer in large sequences. The two grades of Alder we stock are select and tight knot, and much like White Pine, there is a good chance both grades will come from the same log.

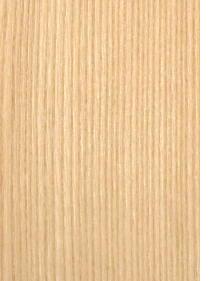

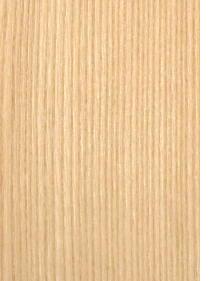

There are several types of Ash native to North America. We stock North American White Ash in plain sliced, plain quarter cut and figured when available. White Ash usually has an amber or light brown tone. Ash can be used as a substitute for Oak at times since their grains are so similar in appearance. I think that Ash and Oak are very similar to work with. Ash does have a little tighter grain though and that could be why the wood bat industry prefers it over Oak.

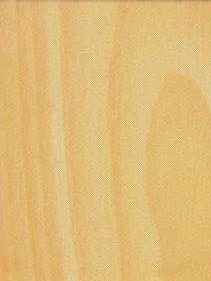

Aspen wood can be found growing around the world but Domestic Quaking Aspen is native to Central and North America which is what we occasionaly stock. Aspen can be very white and at times look very much like Horse Chestnut. We rarely see large quantity's of Aspen veneer and when we have it in stock it will typically be plain sliced and panel length.

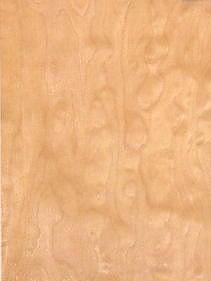

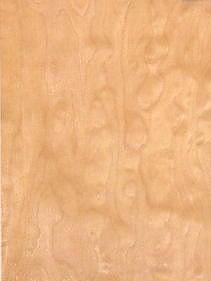

There are probably as many types of Birch in the world as carter has pills. The three types of Birch that are perhaps used the most for domestic production would be Yellow Birch, Sweet Birch and Paper Birch. Paper Birch most likely providing the most decorative appearances of the three. We typically try to stock Red, White and Figured Birch in plain sliced and quarter cut configurations.

The only two Butternuts that I know of grow in North America and Austrailia, the latter of which is in name only. North Anerican Butternut has the botanical name ( Juglans cinerea ) and Walnut has the botanical name ( Juglans nigra ). They also pretty much grow in the same neighborhood, Eastern North America. In my book, that makes them eligible to be cousins. Butternut has a tendency to be pretty rustic for a variety of reasons but can also be very sound and architectural in appearance. Unfortunately, like Alder, you may have to digest a large waste factor to satisfy an architectural requirement. We typically stock Butternut as plain sliced and clip quarters away when necessary.

There are many types of Cedar but for domestics, we only stock Western Red, Aromatic Cedar and occassionlly Port Orford. (See Spanish Cedar in our import section.) Each of these woods has many uses including architectural panel production. The most common Cedar that our customers ask for is vertical grain Western Red Cedar. The look most are after is usually a medium brown tone with little color variation. That is one of the hardest looks to supply because Western Red Cedar colors swing and spike considerably, therefore it requires a lot of high grading. Aromatic Cedar veneer pretty much maintains its classic red brown with sap cedar chest look but can be a little difficult to work with because of its brittleness. Port Orford Cedar has that cross between pine and fir look. It is a very nice wood to work with but is getting increasingly harder to find. Alaska Yellow Cedar is available once and a while and it is very attractive but can be difficult to work with due to its ability to expand and contract wildly at times. Western Red and Port Orford Cedar are soft woods so their vertical grain structure can collapse while under the stress of mechanized splicing. Quite often it is easier to splice the faces together by hand rather than hasseling with trying to fine tune your splicer, if you have one, unless you have a bunch of faces to make and it is worth the time investment.

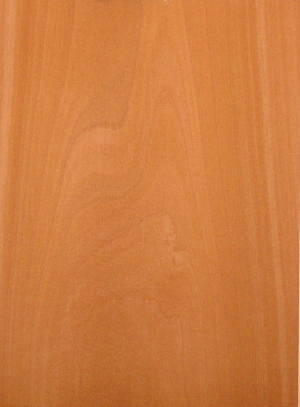

Block Mottled; Curly; Plain Sliced Figured/Flame; Plain Sliced Select; Plain Sliced Rustic; Rift and Rotary are all different descriptions for the various apperances of North American Cherry. We try to keep Flat Cut ( plain sliced ), quarter cut, rift and figured in our inventory as well as rotary and rustic at times. Cherry is a species that has a tendency more often than not to have some figuring in it. The woods popularity never seems to fade but what we have noticed in the last few years is the demand for rift has increased. These days we are more apt to clip rift away from flat cut to get the vertical grain look that some of our customers are after. We have better control of the sequencing that way too.

Chestnut is another wood that has a lot of rustic appeal primarily due to the Asian plant pathogen introduced in the 40's known as Chestnut Blight. I think of New England when I think about Chestnut. We had 20 inch planks in our farm house floors at my grand parents farm in Salisbury, New Hampshire which was built in the late 1700's and they were magnificant. The problem these days is that we can actually find clear panel length Chestnut veneer easier usually than sound wormy to match the old timbers that are reclaimed from century old buildings being torn down. A lot of the wormy chestnut veneer is drilled out to look wormy because the real decomposed wood is to screwed up to do any thing with, plus, it most likely will not be panel lengh, so you can build cut to size panels but struggle to come up with enough veneer to make a couple 4x8's and then you have the color issues. When it comes to sequencing its back to using clear or you can be in for a battle. Waste factors can increase easily when working with wormy Chestnut so warn your customer ahead of time and keep in mind that wormy butternut may be an option if there is more of it available at the time because it just might suit your needs and vice versa.

Elm, American Elm,Gray Elm, Red Elm, Hard Elm, Soft Elm, Slippery Elm, Winged Elm, Rock Elm and Wahoo are all names for Elm that grows in North America. Despite the Dutch Elm rumors there is a lot of Elm growing in the United States and Canada. The issue is that it just isn't that popular so veneer mills choose not to slice any more of it then they are willing to sit on. The most popular colors that we get asked for are red to reddish brown and usually as a rift cut so that is what we try to stock when it is available and people are requesting it. It is a pretty comfortable wood to splice and press and is actually very attractive when sanded and finished. Keep in mind that Elm Burl comes from English Elm. I'm not sure where the term Carpathian comes from if anyone knows please let me know.

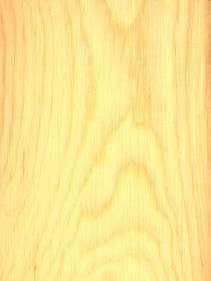

Clear Vertical Grain Douglas Fir is best known for its North West origins but truth be told it grows all over the place including Mexico, Europe, New Zealand and Austrailia. Old growth is very popular for decorative millwork. These days most of the Douglas Fir veneer is sliced from cants and therefore the sequences are not extremely large. The other thing that we run into is that the tighter the architectural grain specs get the shorter the sequences get again because that also means no pitch pockets. That doesn't mean that you cannot get the occasional 2000 square foot sequence, you can, its just not going to happen every day and they will be more expensive than commodity fir. Douglas fir has pitch pockets and the color varies from a straw to red tone. We are asked frequently for veneer that leans more towards a medium brown rather than yellow or red. The result is a higher cost due to the increased amount of grading involved. Larch ( Tamarack )is commonly mixed in with Douglas Fir lumber since it is abundent and its Northern growth range is much more extensive than Fir. Larch however is not generally mixed with Douglas Fir veneer because of its poor architectural grade yield.

Western North American Hemlock is the Washington State tree. It grows through out the Northwest but the stands in Alaska and Canadian forests are the largest. Hemlock can also be found in Eastern North America and some Asian countries. Western Hemlock has a little finer grain than its Eastern cousin. In the veneer world it can be difficult to come up with an abundance of Architectural grade material. The wood is prone to latex stain, rapid decay and black streaks caused by the black fly maggot. We try to keep both flat cut and quarter cut hemlock in inventory. This is a wood that can have rustic charm on one hand yet be contmporary on the other. When it comes to matching, random plank is the easiest to achieve, but most folks want a book or slip match sequence. We have and will do sequential flat and quarter cut lay ups just keep in mind that it can be difficult to come up with large architectural sequences but it's not impossible.

There are several Hickory species but Bitternut hickory is possibly the most widely and uniformly distributed hickory of them all. It grows pretty much all over most of the Eastern half of the United States. Hickory and Pecan are very heavy and hard on knives and blades. We typically do not wide belt sand Hickory any finer than 150 gritt because we find that the belts have a tendancy to get hot quickly and load up causing them to polish and burn rather than cut. We usually have panel length Hickory quarters and or flat cut and at times we will have some with knots and spalting. Hickory in veneer form can have buckle and I try to stay away from it when it does. It can be a pain in the butt to deal with.

Pacific Madrone grows primarily in the coastal lowlands from British Columbia all the way to a few isolated groves in Mexico. It is most commonly found west of the Cascades in Washington and Oregon. Madrone can be beautiful but not with out issues. The long wood has not been a huge commercial success primarily because it spoils easily, has color issues and is prone to fracturing at the ends which can make it difficult to net panel length veneer. We usually have some flat cut and quarters in inventory but I cannot guarantee that it will be panel length. We have had much better success making cut to size panels with this species rather than 4x8 panels.

What can I say about Maple other than it pretty much grows everywhere and has a ton of different names. We typically keep a bunch of different looks in inventory such as plain sliced and figured, quarter cut plain and figured, plain whole piece rotary, burl, quilt, cluster, spalted and birdseye. Our Maple is North American and it ranges from hard rock to big leaf with the color range being very light to orangish brown. The figured woods vary from flitch to flitch so it is necessary to look at samples which we can Email, mail or both.

These three maple specialty appearances have alway's been around just not appreciated until recently. Once they became desireable these woods were then scrutinized for perfection. Quilted Maple has never been a big money maker for the large producers, primarily because it is very difficult to estimate what sort of yield any one log might actually have. As a result, the highly scrutinized appearance and lack of availability has driven the cost to an extreme. Cluster, muscle/angel wing is an appearance that lands some where between burl and quilt. It has a tendancy to be a little more brown in tone plus the waste factor is more like burl. We have built some awesome doors and panels with this wood though. Spalted/rustic maple has alway's been around but for many years was used more for backer and not so much for decorative panel because it just wasn't a particuarly popular look, therefore, it just wasn't profitable for the producers to pursue as decorative. Accept for the odd log, it still isn't all that popular so a big portion of it still ends up as backer just like it traditionaly has. We do keep a small amount of quilt around and typically acquire it in larger quantity's as needed. We do have a fair amount of cluster and a really nice spalted flitch.

The domestic Myrtle wood that we are most familiar with is also commonly called California Laurel. It occurs from Oregon to California. There are other woods around the world that are referred to as Myrtle most of which are growing in the Oceanian and SE Asian parts of the world and in many cases are not true Myrtles. Most crafts men and women are probably more familiar with it in burl form and turning stock apposed to longwood veneer and lumber. I think that Myrtle has a very pleasing rustic barn wood appeal to it. The down side might possibly be the inconsistantcy of its appearance from one cutting to the next, which, you can get with Alder, Hickory and the Oaks etc. We do not stock Myrtle long wood veneer but we do have Myrtle burl veneer. I am being caucious when I say that I am usually able to locate longwood veneer if I have a little time to contact a number of possible sources.

What can any one say about red oak that pretty much all wood workers do not already know? You may not, know, that it is actually pretty popular throughout Europe and is still very popular and plentiful in North America. We do stock plain sliced and quarter cut red oak despite the fact that we do not get a lot of requests for it these days. One thing about red oak is that the log dimensions are still very good and it is a relativly easy wood to work with plus it takes stain and finish very well. Keep in mind that it is not unusual for red Oak veneer to have grain separation which means there is a good chance you will need to get out the paper tape and do some patching. Oak woods in general do display barber poling when book matched as plain sliced or quarter/rift.

Classic White Oak grows from Maine to Texas and its destribution includes at least nine variety's of (Quercus). White Oaks in general grow pretty much all over North America. I am going to go out on a rather stout limb now and say that Rift cut is by far the most popular. We typically have a lot of Rift White Oak and we make a lot of custom architectural panels and doors with it, but, we also have plain sliced, quarter cut, and an awesome figured log that has quarters, flat cut and figured rift.

Pecan and Hickory belong to the same (Carya) family and therefore they are extremely similar. There are more types of Hickory than Pecan and Hickory grows in more places but they do get separated and it is possible to get one or the other. The most common look that we are asked for is a medium to light brown tone and most of the time its Hickory. I associate the darker reds and brown or white sap with Pecan. We do keep some of both species in stock but usually show mill samples for projects that require large sequences and specific appearance. When we make architectural panels we clip sap away and use heart. We had a spec for white Pecan one time and actually found a Pecan flitch that was almost entirely sap to satisfy it. The sequenced cut to size panels were actually very white!

Persimmon is a very dense wood and to me it looks a bit like pine. It has a wide growth range in the South East to South Central US. This wood seems to be used more for its durability and ability to withstand compression as dimensional stock apposed to veneer. We have had it in inventory and as soon as I find more that is worth purchasing I will stock it again. Most of the mill inventory that we find now is quite old.

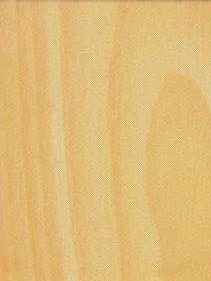

There are lots of Pine woods in North America as well as the rest of the world. We stock and use two Pines, Ponderosa (Yellow) Pine for clear panel because the logs are large enough to get clear veneer and lumber from but the knots are too big for veneer production. White Pine for knotty because the knots are small enough to stay together when sliced. Lodgepole pine finds its way into both productions from time to time as does Sugar Pine. Once in a while we will get in some Eastern White Pine which yields clear and knotty in both veneer and lumber. Pine isn't to bad to work with, although, knots on an edge that is to be spliced, will usually draw back and or crack if heated. Handling Pine, Spruce, Fir, Redwood and Cedar can be frustrating because they all scratch and dent easily.

Poplar is a wood that grows througout the United States, Canada and Europe as poplar and other names like tulipwood and Cottonwood. Yellow poplar especially is capable of being really large, 120 feet with a very straight 2 to 3 foot stem is not unusual. Poplar heart wood has a tendancy to be brown with black and purple streaking which makes it not all that attractive for architectural or paint grade work unlike the sap wood. We are definitly more likely to be asked for sap wood than heart wood. Companys that dye poplar veneer use sap wood. We actually use more Maple and Okoume for laminating and cross banding these days than Poplar but we usually have some in stock.

Redwood is still avalable but inventory's are not abundent. We do have Burl in stock and try to stock long wood when we can or at least be aware of its whereabouts. We usually find quarter and mixed grain. Redwood can be a little difficult to work with at times because its soft enough to crush but brittle enough to crack especially burl. The burl eyes are like most birds eye in that they are hard and the wood around it is usually softer so they can chip away or just fall out. Its not like Mappa Burl though!

Spruce is a very desireable wood in the instrument world and sometimes for the architectural panel world. Sitka Spruce is a coastel species and grows from Alaska to California. Engelman Spruce is an inland species that grows from Alaska to Mexico. White Spruce grows primarily from Alaska all the way across Canada with Red Spruce growing in the North East and Eastern Canada. All of these Spruce woods are used for the construction of instruments as well as many other products. I would say that Sitka is the most desireable for instruments in North America though. All of these woods are typically available in lumber but less likely in veneer. Instrument grade is getting harder and harder to come by due to the width and grain structure. We rarely stock any of the Spruce woods but will accomodate a custom order if at all possible.

North American Sycamore is pretty much a dead ringer for European Plane tree. It also looks and is called Lacewood, which would make it a kin to Australian Silky Oak, South American Lacewood species and European Plane tree. North American Sycamore really doesn't look at all like English Sycamore. This wood is actually very attractive but like all woods that are called Lacewood the waste factor (due to appearance) can be extreme. It really isn't hard to work with and we usually have some in stock.

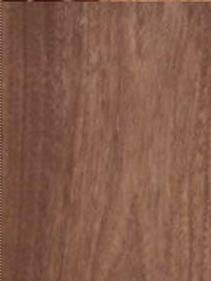

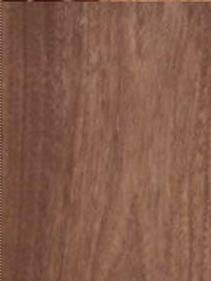

Black Walnut grows throughout the Eastern US but you will see transplanted stands in various locations all over the country. The west coast has what we refer to as Claro Walnut, which, To my understanding, is the result of graphing Eastern Black Walnut and European Walnut together. Walnut has been especially popular the past several years in both plain sliced and rift, especially rift. We typically have plain sliced, rift, quarters, figured, burl and crotch. Keep in mind that book matched Walnut barber poles(especially quarter cut)and it usually doesn't really become obvious until you finish it.

Alder can be found in many countries around the globe. We primarily stock West Coast red/brown Alder in plain sliced and quarter cut. Alder is one of those woods that started out as good firewood and then, due to its rustic appeal, worked its way into many homes and commercial buildings as an attractive and affordable wood for cabinets and finish work. Prices have increased and it has gotten a lot harder to find clear Alder veneer in large sequences. The two grades of Alder we stock are select and tight knot, and much like White Pine, there is a good chance both grades will come from the same log.

Alder can be found in many countries around the globe. We primarily stock West Coast red/brown Alder in plain sliced and quarter cut. Alder is one of those woods that started out as good firewood and then, due to its rustic appeal, worked its way into many homes and commercial buildings as an attractive and affordable wood for cabinets and finish work. Prices have increased and it has gotten a lot harder to find clear Alder veneer in large sequences. The two grades of Alder we stock are select and tight knot, and much like White Pine, there is a good chance both grades will come from the same log.  There are several types of Ash native to North America. We stock North American White Ash in plain sliced, plain quarter cut and figured when available. White Ash usually has an amber or light brown tone. Ash can be used as a substitute for Oak at times since their grains are so similar in appearance. I think that Ash and Oak are very similar to work with. Ash does have a little tighter grain though and that could be why the wood bat industry prefers it over Oak.

There are several types of Ash native to North America. We stock North American White Ash in plain sliced, plain quarter cut and figured when available. White Ash usually has an amber or light brown tone. Ash can be used as a substitute for Oak at times since their grains are so similar in appearance. I think that Ash and Oak are very similar to work with. Ash does have a little tighter grain though and that could be why the wood bat industry prefers it over Oak.  Aspen wood can be found growing around the world but Domestic Quaking Aspen is native to Central and North America which is what we occasionaly stock. Aspen can be very white and at times look very much like Horse Chestnut. We rarely see large quantity's of Aspen veneer and when we have it in stock it will typically be plain sliced and panel length.

Aspen wood can be found growing around the world but Domestic Quaking Aspen is native to Central and North America which is what we occasionaly stock. Aspen can be very white and at times look very much like Horse Chestnut. We rarely see large quantity's of Aspen veneer and when we have it in stock it will typically be plain sliced and panel length. There are probably as many types of Birch in the world as carter has pills. The three types of Birch that are perhaps used the most for domestic production would be Yellow Birch, Sweet Birch and Paper Birch. Paper Birch most likely providing the most decorative appearances of the three. We typically try to stock Red, White and Figured Birch in plain sliced and quarter cut configurations.

There are probably as many types of Birch in the world as carter has pills. The three types of Birch that are perhaps used the most for domestic production would be Yellow Birch, Sweet Birch and Paper Birch. Paper Birch most likely providing the most decorative appearances of the three. We typically try to stock Red, White and Figured Birch in plain sliced and quarter cut configurations. The only two Butternuts that I know of grow in North America and Austrailia, the latter of which is in name only. North Anerican Butternut has the botanical name ( Juglans cinerea ) and Walnut has the botanical name ( Juglans nigra ). They also pretty much grow in the same neighborhood, Eastern North America. In my book, that makes them eligible to be cousins. Butternut has a tendency to be pretty rustic for a variety of reasons but can also be very sound and architectural in appearance. Unfortunately, like Alder, you may have to digest a large waste factor to satisfy an architectural requirement. We typically stock Butternut as plain sliced and clip quarters away when necessary.

The only two Butternuts that I know of grow in North America and Austrailia, the latter of which is in name only. North Anerican Butternut has the botanical name ( Juglans cinerea ) and Walnut has the botanical name ( Juglans nigra ). They also pretty much grow in the same neighborhood, Eastern North America. In my book, that makes them eligible to be cousins. Butternut has a tendency to be pretty rustic for a variety of reasons but can also be very sound and architectural in appearance. Unfortunately, like Alder, you may have to digest a large waste factor to satisfy an architectural requirement. We typically stock Butternut as plain sliced and clip quarters away when necessary.  There are many types of Cedar but for domestics, we only stock Western Red, Aromatic Cedar and occassionlly Port Orford. (See Spanish Cedar in our import section.) Each of these woods has many uses including architectural panel production. The most common Cedar that our customers ask for is vertical grain Western Red Cedar. The look most are after is usually a medium brown tone with little color variation. That is one of the hardest looks to supply because Western Red Cedar colors swing and spike considerably, therefore it requires a lot of high grading. Aromatic Cedar veneer pretty much maintains its classic red brown with sap cedar chest look but can be a little difficult to work with because of its brittleness. Port Orford Cedar has that cross between pine and fir look. It is a very nice wood to work with but is getting increasingly harder to find. Alaska Yellow Cedar is available once and a while and it is very attractive but can be difficult to work with due to its ability to expand and contract wildly at times. Western Red and Port Orford Cedar are soft woods so their vertical grain structure can collapse while under the stress of mechanized splicing. Quite often it is easier to splice the faces together by hand rather than hasseling with trying to fine tune your splicer, if you have one, unless you have a bunch of faces to make and it is worth the time investment.

There are many types of Cedar but for domestics, we only stock Western Red, Aromatic Cedar and occassionlly Port Orford. (See Spanish Cedar in our import section.) Each of these woods has many uses including architectural panel production. The most common Cedar that our customers ask for is vertical grain Western Red Cedar. The look most are after is usually a medium brown tone with little color variation. That is one of the hardest looks to supply because Western Red Cedar colors swing and spike considerably, therefore it requires a lot of high grading. Aromatic Cedar veneer pretty much maintains its classic red brown with sap cedar chest look but can be a little difficult to work with because of its brittleness. Port Orford Cedar has that cross between pine and fir look. It is a very nice wood to work with but is getting increasingly harder to find. Alaska Yellow Cedar is available once and a while and it is very attractive but can be difficult to work with due to its ability to expand and contract wildly at times. Western Red and Port Orford Cedar are soft woods so their vertical grain structure can collapse while under the stress of mechanized splicing. Quite often it is easier to splice the faces together by hand rather than hasseling with trying to fine tune your splicer, if you have one, unless you have a bunch of faces to make and it is worth the time investment.  Block Mottled; Curly; Plain Sliced Figured/Flame; Plain Sliced Select; Plain Sliced Rustic; Rift and Rotary are all different descriptions for the various apperances of North American Cherry. We try to keep Flat Cut ( plain sliced ), quarter cut, rift and figured in our inventory as well as rotary and rustic at times. Cherry is a species that has a tendency more often than not to have some figuring in it. The woods popularity never seems to fade but what we have noticed in the last few years is the demand for rift has increased. These days we are more apt to clip rift away from flat cut to get the vertical grain look that some of our customers are after. We have better control of the sequencing that way too.

Block Mottled; Curly; Plain Sliced Figured/Flame; Plain Sliced Select; Plain Sliced Rustic; Rift and Rotary are all different descriptions for the various apperances of North American Cherry. We try to keep Flat Cut ( plain sliced ), quarter cut, rift and figured in our inventory as well as rotary and rustic at times. Cherry is a species that has a tendency more often than not to have some figuring in it. The woods popularity never seems to fade but what we have noticed in the last few years is the demand for rift has increased. These days we are more apt to clip rift away from flat cut to get the vertical grain look that some of our customers are after. We have better control of the sequencing that way too.  Chestnut is another wood that has a lot of rustic appeal primarily due to the Asian plant pathogen introduced in the 40's known as Chestnut Blight. I think of New England when I think about Chestnut. We had 20 inch planks in our farm house floors at my grand parents farm in Salisbury, New Hampshire which was built in the late 1700's and they were magnificant. The problem these days is that we can actually find clear panel length Chestnut veneer easier usually than sound wormy to match the old timbers that are reclaimed from century old buildings being torn down. A lot of the wormy chestnut veneer is drilled out to look wormy because the real decomposed wood is to screwed up to do any thing with, plus, it most likely will not be panel lengh, so you can build cut to size panels but struggle to come up with enough veneer to make a couple 4x8's and then you have the color issues. When it comes to sequencing its back to using clear or you can be in for a battle. Waste factors can increase easily when working with wormy Chestnut so warn your customer ahead of time and keep in mind that wormy butternut may be an option if there is more of it available at the time because it just might suit your needs and vice versa.

Chestnut is another wood that has a lot of rustic appeal primarily due to the Asian plant pathogen introduced in the 40's known as Chestnut Blight. I think of New England when I think about Chestnut. We had 20 inch planks in our farm house floors at my grand parents farm in Salisbury, New Hampshire which was built in the late 1700's and they were magnificant. The problem these days is that we can actually find clear panel length Chestnut veneer easier usually than sound wormy to match the old timbers that are reclaimed from century old buildings being torn down. A lot of the wormy chestnut veneer is drilled out to look wormy because the real decomposed wood is to screwed up to do any thing with, plus, it most likely will not be panel lengh, so you can build cut to size panels but struggle to come up with enough veneer to make a couple 4x8's and then you have the color issues. When it comes to sequencing its back to using clear or you can be in for a battle. Waste factors can increase easily when working with wormy Chestnut so warn your customer ahead of time and keep in mind that wormy butternut may be an option if there is more of it available at the time because it just might suit your needs and vice versa.  Elm, American Elm,Gray Elm, Red Elm, Hard Elm, Soft Elm, Slippery Elm, Winged Elm, Rock Elm and Wahoo are all names for Elm that grows in North America. Despite the Dutch Elm rumors there is a lot of Elm growing in the United States and Canada. The issue is that it just isn't that popular so veneer mills choose not to slice any more of it then they are willing to sit on. The most popular colors that we get asked for are red to reddish brown and usually as a rift cut so that is what we try to stock when it is available and people are requesting it. It is a pretty comfortable wood to splice and press and is actually very attractive when sanded and finished. Keep in mind that Elm Burl comes from English Elm. I'm not sure where the term Carpathian comes from if anyone knows please let me know.

Elm, American Elm,Gray Elm, Red Elm, Hard Elm, Soft Elm, Slippery Elm, Winged Elm, Rock Elm and Wahoo are all names for Elm that grows in North America. Despite the Dutch Elm rumors there is a lot of Elm growing in the United States and Canada. The issue is that it just isn't that popular so veneer mills choose not to slice any more of it then they are willing to sit on. The most popular colors that we get asked for are red to reddish brown and usually as a rift cut so that is what we try to stock when it is available and people are requesting it. It is a pretty comfortable wood to splice and press and is actually very attractive when sanded and finished. Keep in mind that Elm Burl comes from English Elm. I'm not sure where the term Carpathian comes from if anyone knows please let me know. Clear Vertical Grain Douglas Fir is best known for its North West origins but truth be told it grows all over the place including Mexico, Europe, New Zealand and Austrailia. Old growth is very popular for decorative millwork. These days most of the Douglas Fir veneer is sliced from cants and therefore the sequences are not extremely large. The other thing that we run into is that the tighter the architectural grain specs get the shorter the sequences get again because that also means no pitch pockets. That doesn't mean that you cannot get the occasional 2000 square foot sequence, you can, its just not going to happen every day and they will be more expensive than commodity fir. Douglas fir has pitch pockets and the color varies from a straw to red tone. We are asked frequently for veneer that leans more towards a medium brown rather than yellow or red. The result is a higher cost due to the increased amount of grading involved. Larch ( Tamarack )is commonly mixed in with Douglas Fir lumber since it is abundent and its Northern growth range is much more extensive than Fir. Larch however is not generally mixed with Douglas Fir veneer because of its poor architectural grade yield.

Clear Vertical Grain Douglas Fir is best known for its North West origins but truth be told it grows all over the place including Mexico, Europe, New Zealand and Austrailia. Old growth is very popular for decorative millwork. These days most of the Douglas Fir veneer is sliced from cants and therefore the sequences are not extremely large. The other thing that we run into is that the tighter the architectural grain specs get the shorter the sequences get again because that also means no pitch pockets. That doesn't mean that you cannot get the occasional 2000 square foot sequence, you can, its just not going to happen every day and they will be more expensive than commodity fir. Douglas fir has pitch pockets and the color varies from a straw to red tone. We are asked frequently for veneer that leans more towards a medium brown rather than yellow or red. The result is a higher cost due to the increased amount of grading involved. Larch ( Tamarack )is commonly mixed in with Douglas Fir lumber since it is abundent and its Northern growth range is much more extensive than Fir. Larch however is not generally mixed with Douglas Fir veneer because of its poor architectural grade yield.  Western North American Hemlock is the Washington State tree. It grows through out the Northwest but the stands in Alaska and Canadian forests are the largest. Hemlock can also be found in Eastern North America and some Asian countries. Western Hemlock has a little finer grain than its Eastern cousin. In the veneer world it can be difficult to come up with an abundance of Architectural grade material. The wood is prone to latex stain, rapid decay and black streaks caused by the black fly maggot. We try to keep both flat cut and quarter cut hemlock in inventory. This is a wood that can have rustic charm on one hand yet be contmporary on the other. When it comes to matching, random plank is the easiest to achieve, but most folks want a book or slip match sequence. We have and will do sequential flat and quarter cut lay ups just keep in mind that it can be difficult to come up with large architectural sequences but it's not impossible.

Western North American Hemlock is the Washington State tree. It grows through out the Northwest but the stands in Alaska and Canadian forests are the largest. Hemlock can also be found in Eastern North America and some Asian countries. Western Hemlock has a little finer grain than its Eastern cousin. In the veneer world it can be difficult to come up with an abundance of Architectural grade material. The wood is prone to latex stain, rapid decay and black streaks caused by the black fly maggot. We try to keep both flat cut and quarter cut hemlock in inventory. This is a wood that can have rustic charm on one hand yet be contmporary on the other. When it comes to matching, random plank is the easiest to achieve, but most folks want a book or slip match sequence. We have and will do sequential flat and quarter cut lay ups just keep in mind that it can be difficult to come up with large architectural sequences but it's not impossible.  There are several Hickory species but Bitternut hickory is possibly the most widely and uniformly distributed hickory of them all. It grows pretty much all over most of the Eastern half of the United States. Hickory and Pecan are very heavy and hard on knives and blades. We typically do not wide belt sand Hickory any finer than 150 gritt because we find that the belts have a tendancy to get hot quickly and load up causing them to polish and burn rather than cut. We usually have panel length Hickory quarters and or flat cut and at times we will have some with knots and spalting. Hickory in veneer form can have buckle and I try to stay away from it when it does. It can be a pain in the butt to deal with.

There are several Hickory species but Bitternut hickory is possibly the most widely and uniformly distributed hickory of them all. It grows pretty much all over most of the Eastern half of the United States. Hickory and Pecan are very heavy and hard on knives and blades. We typically do not wide belt sand Hickory any finer than 150 gritt because we find that the belts have a tendancy to get hot quickly and load up causing them to polish and burn rather than cut. We usually have panel length Hickory quarters and or flat cut and at times we will have some with knots and spalting. Hickory in veneer form can have buckle and I try to stay away from it when it does. It can be a pain in the butt to deal with. Pacific Madrone grows primarily in the coastal lowlands from British Columbia all the way to a few isolated groves in Mexico. It is most commonly found west of the Cascades in Washington and Oregon. Madrone can be beautiful but not with out issues. The long wood has not been a huge commercial success primarily because it spoils easily, has color issues and is prone to fracturing at the ends which can make it difficult to net panel length veneer. We usually have some flat cut and quarters in inventory but I cannot guarantee that it will be panel length. We have had much better success making cut to size panels with this species rather than 4x8 panels.

Pacific Madrone grows primarily in the coastal lowlands from British Columbia all the way to a few isolated groves in Mexico. It is most commonly found west of the Cascades in Washington and Oregon. Madrone can be beautiful but not with out issues. The long wood has not been a huge commercial success primarily because it spoils easily, has color issues and is prone to fracturing at the ends which can make it difficult to net panel length veneer. We usually have some flat cut and quarters in inventory but I cannot guarantee that it will be panel length. We have had much better success making cut to size panels with this species rather than 4x8 panels.  What can I say about Maple other than it pretty much grows everywhere and has a ton of different names. We typically keep a bunch of different looks in inventory such as plain sliced and figured, quarter cut plain and figured, plain whole piece rotary, burl, quilt, cluster, spalted and birdseye. Our Maple is North American and it ranges from hard rock to big leaf with the color range being very light to orangish brown. The figured woods vary from flitch to flitch so it is necessary to look at samples which we can Email, mail or both.

What can I say about Maple other than it pretty much grows everywhere and has a ton of different names. We typically keep a bunch of different looks in inventory such as plain sliced and figured, quarter cut plain and figured, plain whole piece rotary, burl, quilt, cluster, spalted and birdseye. Our Maple is North American and it ranges from hard rock to big leaf with the color range being very light to orangish brown. The figured woods vary from flitch to flitch so it is necessary to look at samples which we can Email, mail or both.  These three maple specialty appearances have alway's been around just not appreciated until recently. Once they became desireable these woods were then scrutinized for perfection. Quilted Maple has never been a big money maker for the large producers, primarily because it is very difficult to estimate what sort of yield any one log might actually have. As a result, the highly scrutinized appearance and lack of availability has driven the cost to an extreme. Cluster, muscle/angel wing is an appearance that lands some where between burl and quilt. It has a tendancy to be a little more brown in tone plus the waste factor is more like burl. We have built some awesome doors and panels with this wood though. Spalted/rustic maple has alway's been around but for many years was used more for backer and not so much for decorative panel because it just wasn't a particuarly popular look, therefore, it just wasn't profitable for the producers to pursue as decorative. Accept for the odd log, it still isn't all that popular so a big portion of it still ends up as backer just like it traditionaly has. We do keep a small amount of quilt around and typically acquire it in larger quantity's as needed. We do have a fair amount of cluster and a really nice spalted flitch.

These three maple specialty appearances have alway's been around just not appreciated until recently. Once they became desireable these woods were then scrutinized for perfection. Quilted Maple has never been a big money maker for the large producers, primarily because it is very difficult to estimate what sort of yield any one log might actually have. As a result, the highly scrutinized appearance and lack of availability has driven the cost to an extreme. Cluster, muscle/angel wing is an appearance that lands some where between burl and quilt. It has a tendancy to be a little more brown in tone plus the waste factor is more like burl. We have built some awesome doors and panels with this wood though. Spalted/rustic maple has alway's been around but for many years was used more for backer and not so much for decorative panel because it just wasn't a particuarly popular look, therefore, it just wasn't profitable for the producers to pursue as decorative. Accept for the odd log, it still isn't all that popular so a big portion of it still ends up as backer just like it traditionaly has. We do keep a small amount of quilt around and typically acquire it in larger quantity's as needed. We do have a fair amount of cluster and a really nice spalted flitch.  The domestic Myrtle wood that we are most familiar with is also commonly called California Laurel. It occurs from Oregon to California. There are other woods around the world that are referred to as Myrtle most of which are growing in the Oceanian and SE Asian parts of the world and in many cases are not true Myrtles. Most crafts men and women are probably more familiar with it in burl form and turning stock apposed to longwood veneer and lumber. I think that Myrtle has a very pleasing rustic barn wood appeal to it. The down side might possibly be the inconsistantcy of its appearance from one cutting to the next, which, you can get with Alder, Hickory and the Oaks etc. We do not stock Myrtle long wood veneer but we do have Myrtle burl veneer. I am being caucious when I say that I am usually able to locate longwood veneer if I have a little time to contact a number of possible sources.

The domestic Myrtle wood that we are most familiar with is also commonly called California Laurel. It occurs from Oregon to California. There are other woods around the world that are referred to as Myrtle most of which are growing in the Oceanian and SE Asian parts of the world and in many cases are not true Myrtles. Most crafts men and women are probably more familiar with it in burl form and turning stock apposed to longwood veneer and lumber. I think that Myrtle has a very pleasing rustic barn wood appeal to it. The down side might possibly be the inconsistantcy of its appearance from one cutting to the next, which, you can get with Alder, Hickory and the Oaks etc. We do not stock Myrtle long wood veneer but we do have Myrtle burl veneer. I am being caucious when I say that I am usually able to locate longwood veneer if I have a little time to contact a number of possible sources.  What can any one say about red oak that pretty much all wood workers do not already know? You may not, know, that it is actually pretty popular throughout Europe and is still very popular and plentiful in North America. We do stock plain sliced and quarter cut red oak despite the fact that we do not get a lot of requests for it these days. One thing about red oak is that the log dimensions are still very good and it is a relativly easy wood to work with plus it takes stain and finish very well. Keep in mind that it is not unusual for red Oak veneer to have grain separation which means there is a good chance you will need to get out the paper tape and do some patching. Oak woods in general do display barber poling when book matched as plain sliced or quarter/rift.

What can any one say about red oak that pretty much all wood workers do not already know? You may not, know, that it is actually pretty popular throughout Europe and is still very popular and plentiful in North America. We do stock plain sliced and quarter cut red oak despite the fact that we do not get a lot of requests for it these days. One thing about red oak is that the log dimensions are still very good and it is a relativly easy wood to work with plus it takes stain and finish very well. Keep in mind that it is not unusual for red Oak veneer to have grain separation which means there is a good chance you will need to get out the paper tape and do some patching. Oak woods in general do display barber poling when book matched as plain sliced or quarter/rift. Classic White Oak grows from Maine to Texas and its destribution includes at least nine variety's of (Quercus). White Oaks in general grow pretty much all over North America. I am going to go out on a rather stout limb now and say that Rift cut is by far the most popular. We typically have a lot of Rift White Oak and we make a lot of custom architectural panels and doors with it, but, we also have plain sliced, quarter cut, and an awesome figured log that has quarters, flat cut and figured rift.

Classic White Oak grows from Maine to Texas and its destribution includes at least nine variety's of (Quercus). White Oaks in general grow pretty much all over North America. I am going to go out on a rather stout limb now and say that Rift cut is by far the most popular. We typically have a lot of Rift White Oak and we make a lot of custom architectural panels and doors with it, but, we also have plain sliced, quarter cut, and an awesome figured log that has quarters, flat cut and figured rift.  Pecan and Hickory belong to the same (Carya) family and therefore they are extremely similar. There are more types of Hickory than Pecan and Hickory grows in more places but they do get separated and it is possible to get one or the other. The most common look that we are asked for is a medium to light brown tone and most of the time its Hickory. I associate the darker reds and brown or white sap with Pecan. We do keep some of both species in stock but usually show mill samples for projects that require large sequences and specific appearance. When we make architectural panels we clip sap away and use heart. We had a spec for white Pecan one time and actually found a Pecan flitch that was almost entirely sap to satisfy it. The sequenced cut to size panels were actually very white!

Pecan and Hickory belong to the same (Carya) family and therefore they are extremely similar. There are more types of Hickory than Pecan and Hickory grows in more places but they do get separated and it is possible to get one or the other. The most common look that we are asked for is a medium to light brown tone and most of the time its Hickory. I associate the darker reds and brown or white sap with Pecan. We do keep some of both species in stock but usually show mill samples for projects that require large sequences and specific appearance. When we make architectural panels we clip sap away and use heart. We had a spec for white Pecan one time and actually found a Pecan flitch that was almost entirely sap to satisfy it. The sequenced cut to size panels were actually very white!  Persimmon is a very dense wood and to me it looks a bit like pine. It has a wide growth range in the South East to South Central US. This wood seems to be used more for its durability and ability to withstand compression as dimensional stock apposed to veneer. We have had it in inventory and as soon as I find more that is worth purchasing I will stock it again. Most of the mill inventory that we find now is quite old.

Persimmon is a very dense wood and to me it looks a bit like pine. It has a wide growth range in the South East to South Central US. This wood seems to be used more for its durability and ability to withstand compression as dimensional stock apposed to veneer. We have had it in inventory and as soon as I find more that is worth purchasing I will stock it again. Most of the mill inventory that we find now is quite old. There are lots of Pine woods in North America as well as the rest of the world. We stock and use two Pines, Ponderosa (Yellow) Pine for clear panel because the logs are large enough to get clear veneer and lumber from but the knots are too big for veneer production. White Pine for knotty because the knots are small enough to stay together when sliced. Lodgepole pine finds its way into both productions from time to time as does Sugar Pine. Once in a while we will get in some Eastern White Pine which yields clear and knotty in both veneer and lumber. Pine isn't to bad to work with, although, knots on an edge that is to be spliced, will usually draw back and or crack if heated. Handling Pine, Spruce, Fir, Redwood and Cedar can be frustrating because they all scratch and dent easily.

There are lots of Pine woods in North America as well as the rest of the world. We stock and use two Pines, Ponderosa (Yellow) Pine for clear panel because the logs are large enough to get clear veneer and lumber from but the knots are too big for veneer production. White Pine for knotty because the knots are small enough to stay together when sliced. Lodgepole pine finds its way into both productions from time to time as does Sugar Pine. Once in a while we will get in some Eastern White Pine which yields clear and knotty in both veneer and lumber. Pine isn't to bad to work with, although, knots on an edge that is to be spliced, will usually draw back and or crack if heated. Handling Pine, Spruce, Fir, Redwood and Cedar can be frustrating because they all scratch and dent easily.  Poplar is a wood that grows througout the United States, Canada and Europe as poplar and other names like tulipwood and Cottonwood. Yellow poplar especially is capable of being really large, 120 feet with a very straight 2 to 3 foot stem is not unusual. Poplar heart wood has a tendancy to be brown with black and purple streaking which makes it not all that attractive for architectural or paint grade work unlike the sap wood. We are definitly more likely to be asked for sap wood than heart wood. Companys that dye poplar veneer use sap wood. We actually use more Maple and Okoume for laminating and cross banding these days than Poplar but we usually have some in stock.

Poplar is a wood that grows througout the United States, Canada and Europe as poplar and other names like tulipwood and Cottonwood. Yellow poplar especially is capable of being really large, 120 feet with a very straight 2 to 3 foot stem is not unusual. Poplar heart wood has a tendancy to be brown with black and purple streaking which makes it not all that attractive for architectural or paint grade work unlike the sap wood. We are definitly more likely to be asked for sap wood than heart wood. Companys that dye poplar veneer use sap wood. We actually use more Maple and Okoume for laminating and cross banding these days than Poplar but we usually have some in stock. Redwood is still avalable but inventory's are not abundent. We do have Burl in stock and try to stock long wood when we can or at least be aware of its whereabouts. We usually find quarter and mixed grain. Redwood can be a little difficult to work with at times because its soft enough to crush but brittle enough to crack especially burl. The burl eyes are like most birds eye in that they are hard and the wood around it is usually softer so they can chip away or just fall out. Its not like Mappa Burl though!

Redwood is still avalable but inventory's are not abundent. We do have Burl in stock and try to stock long wood when we can or at least be aware of its whereabouts. We usually find quarter and mixed grain. Redwood can be a little difficult to work with at times because its soft enough to crush but brittle enough to crack especially burl. The burl eyes are like most birds eye in that they are hard and the wood around it is usually softer so they can chip away or just fall out. Its not like Mappa Burl though!  Spruce is a very desireable wood in the instrument world and sometimes for the architectural panel world. Sitka Spruce is a coastel species and grows from Alaska to California. Engelman Spruce is an inland species that grows from Alaska to Mexico. White Spruce grows primarily from Alaska all the way across Canada with Red Spruce growing in the North East and Eastern Canada. All of these Spruce woods are used for the construction of instruments as well as many other products. I would say that Sitka is the most desireable for instruments in North America though. All of these woods are typically available in lumber but less likely in veneer. Instrument grade is getting harder and harder to come by due to the width and grain structure. We rarely stock any of the Spruce woods but will accomodate a custom order if at all possible.

Spruce is a very desireable wood in the instrument world and sometimes for the architectural panel world. Sitka Spruce is a coastel species and grows from Alaska to California. Engelman Spruce is an inland species that grows from Alaska to Mexico. White Spruce grows primarily from Alaska all the way across Canada with Red Spruce growing in the North East and Eastern Canada. All of these Spruce woods are used for the construction of instruments as well as many other products. I would say that Sitka is the most desireable for instruments in North America though. All of these woods are typically available in lumber but less likely in veneer. Instrument grade is getting harder and harder to come by due to the width and grain structure. We rarely stock any of the Spruce woods but will accomodate a custom order if at all possible.  North American Sycamore is pretty much a dead ringer for European Plane tree. It also looks and is called Lacewood, which would make it a kin to Australian Silky Oak, South American Lacewood species and European Plane tree. North American Sycamore really doesn't look at all like English Sycamore. This wood is actually very attractive but like all woods that are called Lacewood the waste factor (due to appearance) can be extreme. It really isn't hard to work with and we usually have some in stock.

North American Sycamore is pretty much a dead ringer for European Plane tree. It also looks and is called Lacewood, which would make it a kin to Australian Silky Oak, South American Lacewood species and European Plane tree. North American Sycamore really doesn't look at all like English Sycamore. This wood is actually very attractive but like all woods that are called Lacewood the waste factor (due to appearance) can be extreme. It really isn't hard to work with and we usually have some in stock. Black Walnut grows throughout the Eastern US but you will see transplanted stands in various locations all over the country. The west coast has what we refer to as Claro Walnut, which, To my understanding, is the result of graphing Eastern Black Walnut and European Walnut together. Walnut has been especially popular the past several years in both plain sliced and rift, especially rift. We typically have plain sliced, rift, quarters, figured, burl and crotch. Keep in mind that book matched Walnut barber poles(especially quarter cut)and it usually doesn't really become obvious until you finish it.

Black Walnut grows throughout the Eastern US but you will see transplanted stands in various locations all over the country. The west coast has what we refer to as Claro Walnut, which, To my understanding, is the result of graphing Eastern Black Walnut and European Walnut together. Walnut has been especially popular the past several years in both plain sliced and rift, especially rift. We typically have plain sliced, rift, quarters, figured, burl and crotch. Keep in mind that book matched Walnut barber poles(especially quarter cut)and it usually doesn't really become obvious until you finish it.